Objectives

Objectives

Propose a methodology for designing cooperative systems

-

to support the Human operator in the Factory of the Future:

-

to maintain situation awareness

-

to make decision

-

to manage uncertainties

-

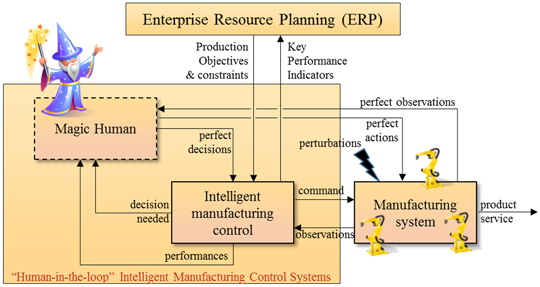

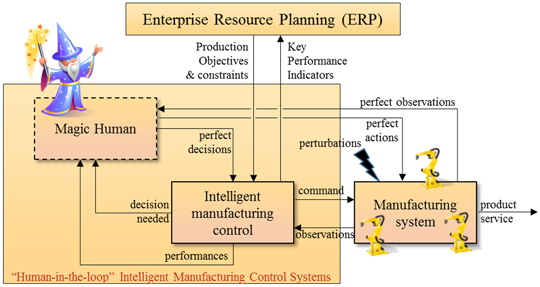

to limit shortcomings such as considering the Human operator as a« Magic Human »

-

and so:

-

to offset the increase in systems complexity

-

and to increase production systems performance

Bringing together Engineering and Human Sciences

Hypothesis

Hypothesis

Evaluation of several approaches

-

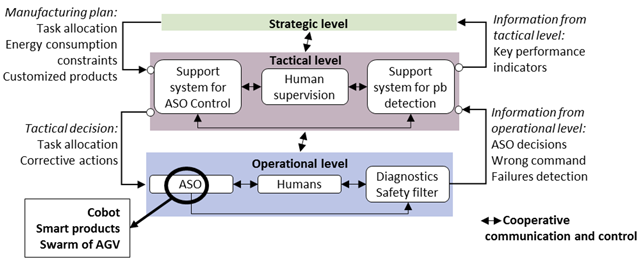

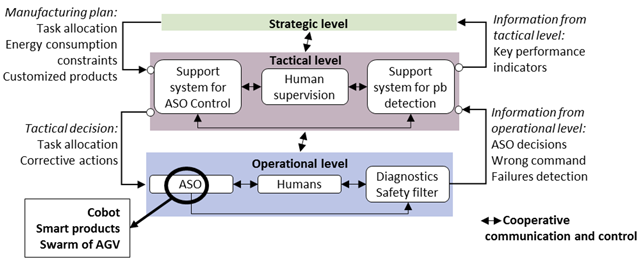

Validation of the « cognitive work analysis » approach in order to design production systems of the future integrating Human

-

Validation of the supervisory approach promoting « situation awareness » and a « common work space »

-

Designing tools to enable incident detection management (« safety filter », « model-checking »)

-

Designing levels of automation adaptable to self-organized systems interacting with Human (AGV, robot, Cobot…)

Objectives

Objectives Hypothesis

Hypothesis