Optimizing and manufacturing innovative piezoelectric sensors: a coupled approach between mathematical modeling and 3D printing

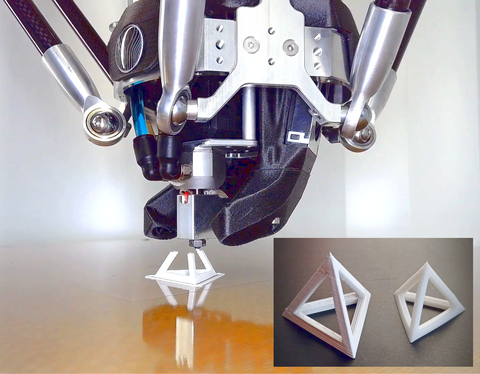

The PonArcad (2026) project, led by a multidisciplinary team within the CERAMATHS laboratory, is taking place under the laboratory's own Appel à projet action incitative (ARI). The project combines the expertise of the DMATHS (mathematical modeling) and DMP (experimental manufacturing) departments. Its ambition: to design piezoelectric sensors with innovative geometries, such as bridges or arches, to reduce material consumption while optimizing their electromechanical efficiency. This approach is based on a novel coupling between theoretical modeling, numerical simulations (Python/COMSOL) and additive manufacturing (3D printing, laser cutting).

.The team of five researchers is evenly divided between the two departments. Mohammad Akil, Serge Nicaise and Matthias Täufer (DMATHS) focus on modeling, topological optimization and homogenization, while Mohamed Benachour and Mohamed Rguiti (DMP) steer the fabrication and electrical characterization of prototypes. This sharing of roles guarantees optimum synergy between theory and practice.

The project is structured around a precise timetable: the first three months of 2026 will be devoted to developing theoretical models. From April to June, the DMP will run the first simulations and build prototypes. The second half of the year will be dedicated to comparing experimental results with model predictions, as well as optimizing geometries, before finalization by 3D printing.

.The originality of PonArcad lies in its integrated approach, which combines modeling and manufacturing to create a reproducible methodology. The project aims to understand the influence of geometry on sensor performance, identify key parameters and develop simplified topological optimization tools, applicable to other materials or devices.

On the collaborative front, the project relies on monthly exchanges between the two departments and an international collaboration with the LabSIPE laboratory (Morocco). This partnership, formalized by a cotutelle thesis, will enable advanced applications to be explored, such as the use of AI for data interpretation or sensor testing in real-life conditions.

Expected results include the development of simplified models, accessible simulation tools, and optimized, experimentally validated prototypes. Advances will be disseminated via scientific publications and conferences, strengthening interdisciplinary links within CERAMATHS. This project lays the foundations for future ambitious work in the field of intelligent piezoelectric sensors, combining performance and durability.