Experimentation

- Objective 1: Highlight the advantages of using hybrid control architectures

- Objective 2: Demonstrate the feasibility of ORCA-FMS.

1) Experimental Protocol:

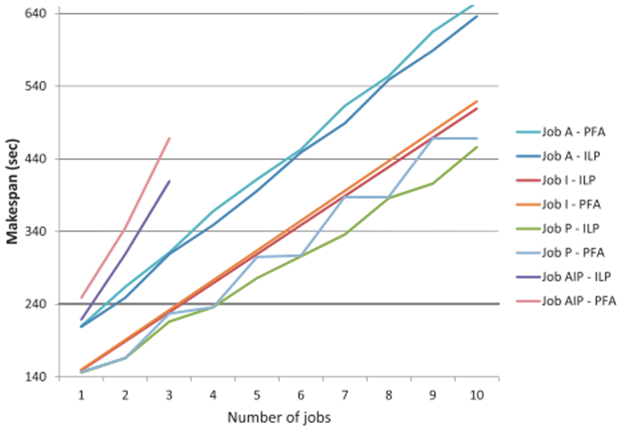

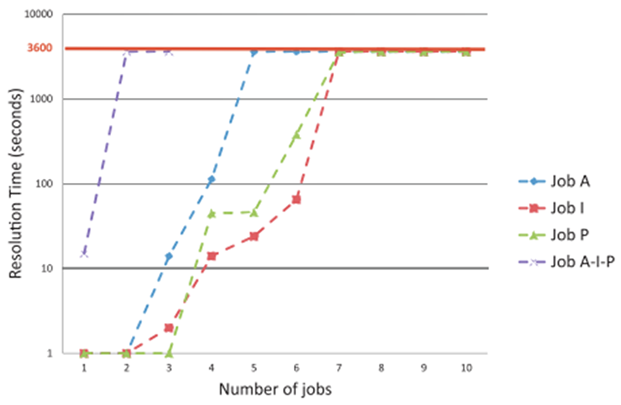

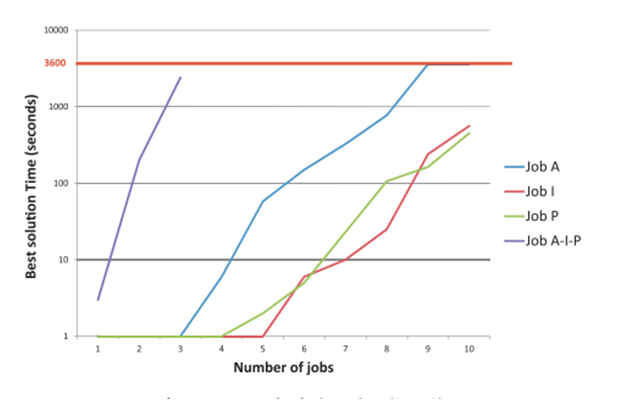

For step 1, 2 and 3, the experiments used the ‘‘Test Group 1”, which contains 33 different production campaigns with for each a growing number of jobs:

- From 1A job to 10A jobs

- From 1I job to 10I jobs

- From 1P job to 10P jobs

- From 1 A-I-P job to 3 A-I-P jobs

For 3 A-I-P, the production campaign contained nine jobs and the resolution time reached a pre-set upper resolution time limit of 1 h for ILP, which is why no experiments were carried out with more complex production campaigns.

Step 1. Execution without perturbation and with the Cmax as performance indicator (C max for ILP and PF)

Step 2. Execution without perturbationand with the Resolution time as performance indicator (Finding and proving the optimality of the ILP solution)

Step 3. Execution without perturbation and a Good solution time as performance indicator (finding a solution better than the PF with the ILP)

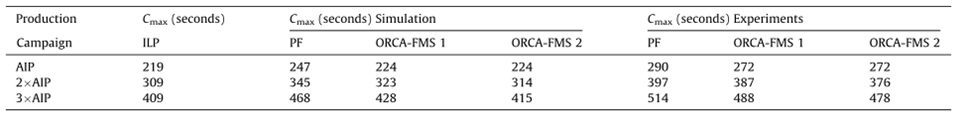

For step 4, the experiment used the ‘‘Test Group 2’’ which contained the following campaigns:

From 1 A-I-P job to 3 A-I-P jobs.

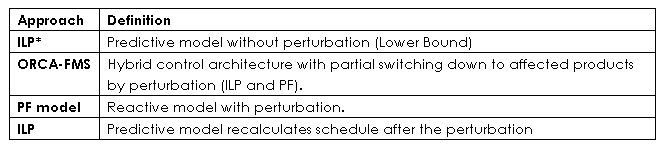

ORCA-FMS has two hybridization levels:

- ORCA-FMS 1 uses the ILP solver to provide only the job order.

- ORCA-FMS 2 uses the ILP solver to provide the job order and the machine sequence.

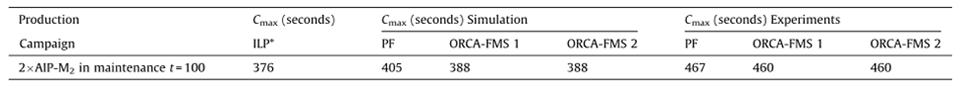

Results are provided with the ILP, PF, ORCA-FMS 1, and ORCA-FMS 2 in simulation and real experiments using the AIP cell.

Step 4. Execution with perturbation and the Cmax as performance indicator

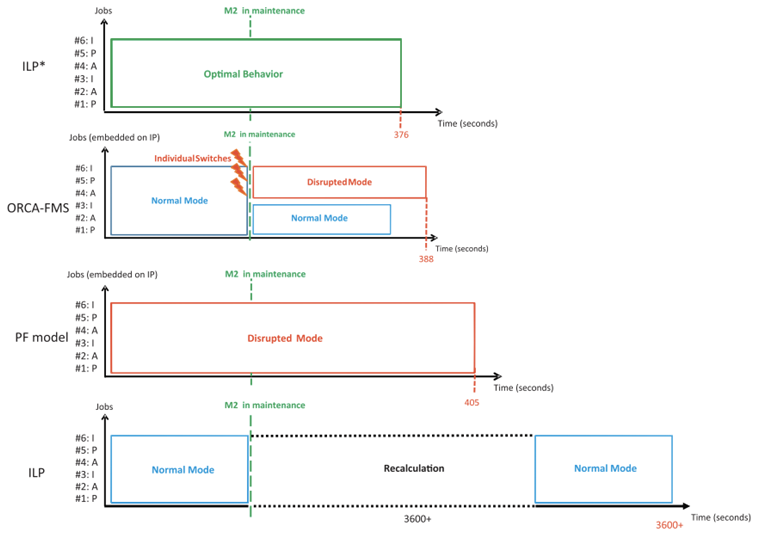

For step 5, the experiment used the ‘‘Test Group 3’’ which contained the following campaign:

2 A-I-P

This experiment is a simulated scenario with perturbation. In this scenario, the machine M2 enters to maintenance, and no job can be allocated to it after t = 100 s. This machine remains unavailable until the end of production.

2) Comparisons of behavioral approaches

3) Conclusions

Using ORCA-FMS, all the jobs were manufactured and production was completed with only a short delay (compared to the duration of the perturbation). In this production campaign three jobs were manufactured in normal mode and three in disrupted mode in the same time. This highlights the dynamics of the control structure and the interest of partially switching to disrupted mode for some IPs and not for others.