MILP format model

The studied system can be viewed as a Flexible Job Shop manufacturing system. Each job, composed of a few operations, has its own operating set. A service can be performed on specific set of resources located in the manufacturing system. Each resource can perform a set of different operations.

In addition to the traditional constraints of FJSP, the following constraints related to the realistic features of the system are considered:

- Transportation time between machines is considered.

- An input stock or queue on each resource is managed by the First In, First Out (FIFO) rule.

- The resource queue has a limited capacity that should be respected,

- The number of simultaneous jobs in the system can be limited.

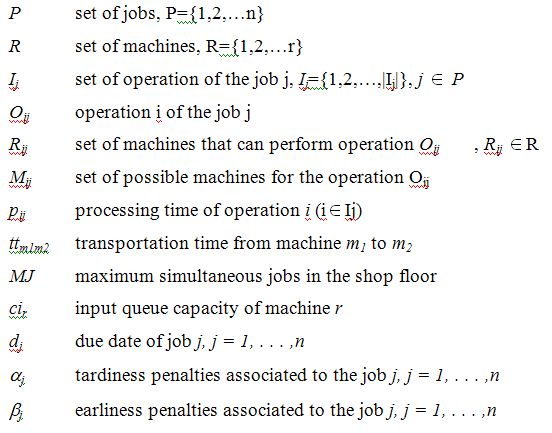

Notations for parameters

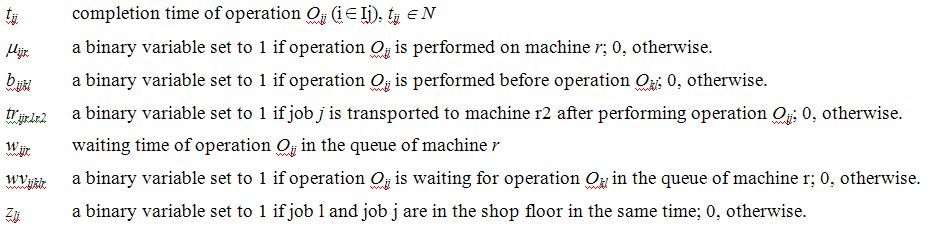

Notations for variables

Detail of the constraints

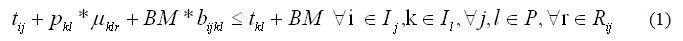

Disjunctive constraints: A machine can process one operation at time, and an operation is performed by only one machine.

where BM is a large number.

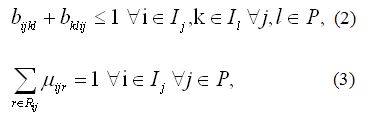

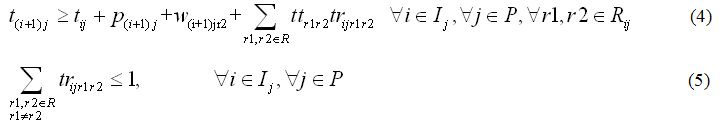

Precedence constraints: These constraints insure job’s production sequence. The completion time of the next operation considers the completion time of the previous one, the waiting time and the transportation time if the two operations are not performed in the same machine.

Allocation and transportation relationship: If successive operations of a job are performed on different machines, there is a transportation operation between those two machines. Transportation delays are set to zero, and the transportation system has unlimited capacity.

where ε is a small number.

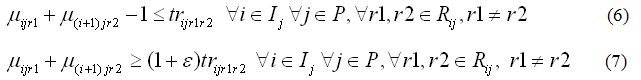

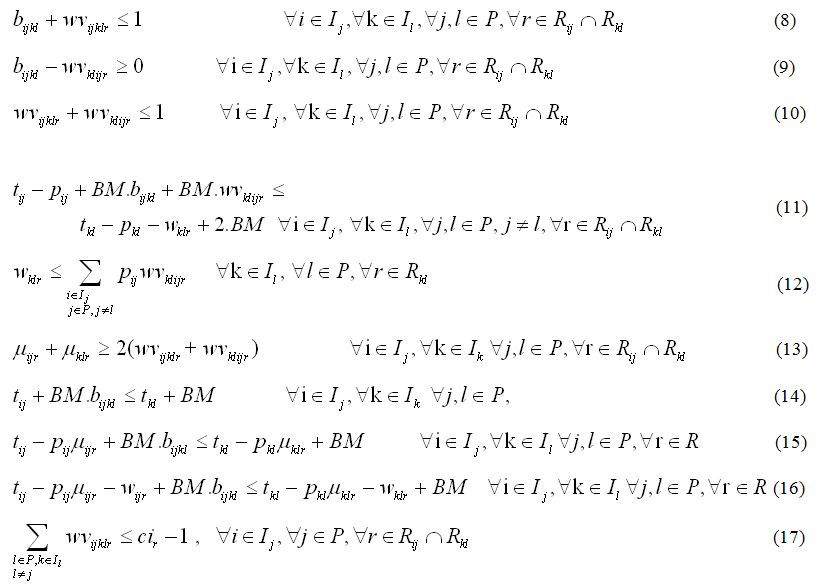

Queue capacity of the machine input and FIFO rule: Each machine has a limited queue capacity. No more operations than this queue capacity can wait in the queue. The first job arriving in the queue is the first treated.

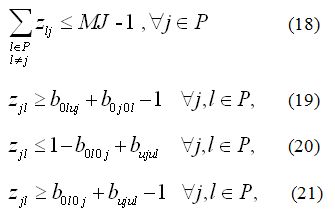

Limitation of the number of jobs in the system: The number of simultaneous jobs in the shop floor can be limited by MJ. O0j defines the first operation the job j (i.e., loading), and Ouj defines the last one (i.e., unloading).

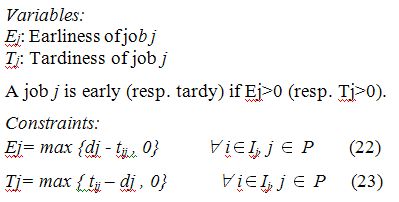

Variables and constraints in the case of due-date based production

Some constraints and variables must be added only in the case of due-date-based production.

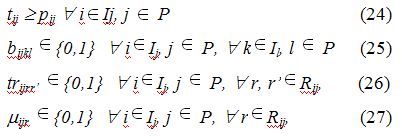

Constraints for the type of each variable

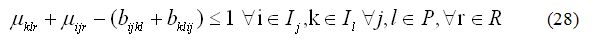

A valid inequality

The following cut is added to the model to improve the solving. Note that this constraint makes the link between the precedence variables and the machine allocation. It is not cited in the paper.

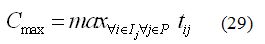

Quantitative performance

Different criteria are used in the measurement of the quantitative performance. The well-known criteria are cited below, according to the variables and parameters presented above.

Makespan Cmax is the time at which the last job is completed:

Earliness and Tardiness of jobs is the comparison of the actual completion time of jobs with the desired completion time. The earliness of a job i is the positive difference between the due date and the completion time (eq. 30). In the opposite way, the tardiness Ti of a job i is the positive difference between the completion time and the due date(eq. 31) . Different criteria can be minimized: the amount of earliness (eq. 32), the amount of tardiness (eq. 33) or both criteria (eq. 34, or its quadratic form).

where αi and βi are respectively delay cost and handling cost.