SOFTMAT

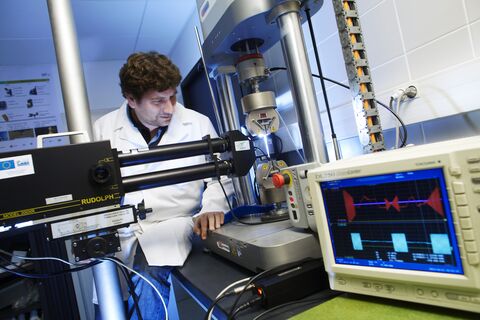

Our SOFTMAT platform consists of a set of equipment dedicated to the characterization of materials and structures under extreme conditions of temperature, loading and strain rate and for various materials (metallic, polymers, composites, organic)

.General presentation

In particular, our SOFTMAT platform enables us to identify thermo-viscoelastic and viscoplastic behavior laws that can be damaged at different speeds and temperatures (PP,filled PP, HDPE, bone, gel, etc). Appropriate measurement tools have been developed for this purpose (specific mounting, non-contact displacement measurement, 2D and 3D image correlation, etc.)

.This platform is consequently widely associated with research activities whether academic or industrial.

It is part of the DM2SE regional platform and continues its development through the RITMEA project, co-funded as part of the contrat de plan État Région (CPER 2021-2027) and the OP Féder (2021 - 2027).

Key words

Crash, ballistics, bonded assembly, traumatology, polymers, behavior law, testing, substitutes, digital, identification, biological glue joint,bonding

Skills

- Characterization of low-stiffness materials and structures (PP, filled PP, HDPE, biological, gel, etc.) at different strain rates (from 10-4 to 10² s-1 ) and temperatures (-100 to 350°C) under different loadings (monotonic, alternating, cyclic, DMA)

- Architectural characterization (from microscopic to macroscopic scale) of high-density materials (biological, semi-crystalline, etc)

- Non-contact measurement by optical extensometry, image correlation and stereocorrelation, infrared temperature measurement.

- Static, dynamic and temperature characterization of adhesives on Bulk test or dynamic ARCAN test.

- Identification of behavior law parameters for finite element calculations

Examples of work

- Identification of the mechanical behavior of human rib cortical bone under different loadings.

- Identification of viscoelastic/viscoplastic parameters on semi-crystalline and bio-sourced polymers

- Dynamic behavior of a head substitute subjected to ballistic loading.

- Determination of the distribution and orientation of short fibers in a polymer matrix

- Study of the evolution of architecture and strain distribution during µtraction tests on biological materials (cortical bone, cancellous bone, etc) and polymers (talc-filled PP, natural fibers, etc)

Collaborations

- Companies: SAFRAN, FAURECIA, RENAULT, TOYOTA, CIMES, DECATHLON, APERAM, STELLANTIS, NOVARES, ISL, SMRC Automotive

- Research: ONERA, LAMCUBE, Ministere de l'intérieur, DGA, U-Mons, NTNU, Université Gustave Eifel, UTBM, Université de Strasbourg, Wayne State University, Université de Sfax, IRDL

Equipment

| Equipment name | Model | Make |

|---|---|---|

| Electropuls test machine |

E3000 |

Instron |

|

Dynamic mechanical analyzer (DMA) |

DMA 850 |

TA Instruments |

| 76kW asynchronous load machine |

CPLS 132L |

PATAY |

| µ x-ray tomography with in situ testing possible | 1172 | Skyscan Bruker |

| Thermal Enclosure (-100 to 350°c) | 3119-605 | Instron |