PUVAFIN

PUrification and VAlorization of Industrial Fumes

The PUVAFIN project aims to develop an innovative solution for the purification and recovery of industrial fumes, particularly those generated by incinerators, in order to combine environmental efficiency, technical feasibility and economic viability.

Presentation

Waste management and the reduction of polluting emissions have become major imperatives for communities, industries and citizens.

Waste incineration, although often used as a local treatment solution, generates fumes rich in toxic substances such as fine particles, nitrogen oxides (NOₓ), volatile organic compounds (VOCs)...

These emissions, when not properly treated, have repercussions on public health, air quality and ecosystems.

With this in mind, the PUVAFIN project aims to develop an innovative solution for the purification and recovery of industrial incinerator fumes.

This project is based on a technology to improve combustion by recirculating gases and promoting oxycombustion.

The process should enable CO2 to be reinjected from the flue gases, replacing the nitrogen present in pure air. This will increase the concentration of CO2 at the chimney outlet, making it easier to convert it back into methane or methanol afterwards.

The process must be able to reinject CO2 from the flue gases, replacing the nitrogen present in the pure air.

The aim of the project is to implement the selected technology on a waste incinerator.

But before any industrial integration, it is essential to assess the impact of this strategy on the combustion process as well as on the associated pollutant emissions.

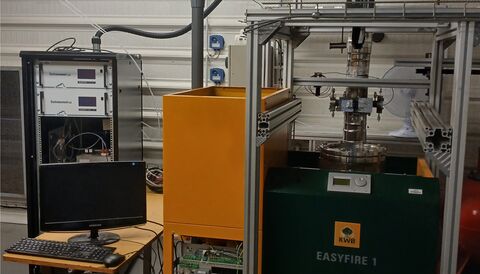

Thus, the envisaged process will be validated on a boiler installed at LAMIH, within the framework of biomass and household waste combustion.

Combustion pollutants will be washed-mixed, thanks to the system developed allowing high-concentration CO2 to be reinjected at the boiler inlet.

.The emissions will then be characterized with advanced diagnostics to determine the extent to which they can be reduced using the innovative process developed.

Keywords

Oxycombustion, pollutant emissions, waste, purification, flue gas recovery